Metrix™

Applications:

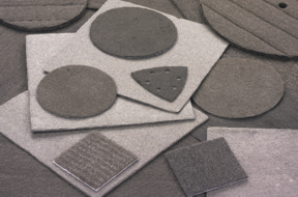

Any industrial application where a non-woven metallic fabric is required. Filtration, head shielding, noise attenuation, structural panel reinforcement, composite reinforcement and electrical conductivity are typical applications for our Metrix materials.

Benefits:

- The random fiber distribution of the process provides a uniform material

- Metrix non-wovens exhibit superior mechanical properties

- Very high density structures are possible owing to the mechanical interlocking of the fibers

- To further improve the physical properties, sintered product have been developed

- The media is strong, porous, flexible and easily fabricated

- We have the ability to sinter-laminate our materials to other metal media such as wire cloth, perforated metal etc.

General Information:

Metrix products are produced to specifications designed by our customers. Below are some of the basic parameters of our Metrix materials.

MATERIALS: Metrix is currently available in carbon steel, 434 alloy stainless steel, copper and brass. Addition of 300 series stainless steel, bronze, nickel & nickel alloys and other exotic metal fibers is planned.

FIBER SIZES: The range of typical fiber sizes of conventional GMT metal fibers is available in most materials from 25 to 125 microns. Other types of fiber may be incorporated into the process and are available upon request.

BASIS WEIGHTS: Common basis weights from 200 g/m² to 4 kg/m², with other weights possible upon request.

THICKNESS: Individual basis weights are available in high and low loft versions, and can also be calendered to further improve strength and flatness. Sintering may be employed to further alter thickness, strength and other attributes.

FORMAT: Available in rolls of any width up to 2.6 meters (105 inches) wide, sheets, seamless tube or die cut into shapes and packed as required.

TOLERANCES: Capable of thickness tolerances within ±10%, basis weight tolerances within ±15% or as specified. Fiber size tolerances are dependent upon the type of fiber(s) selected.